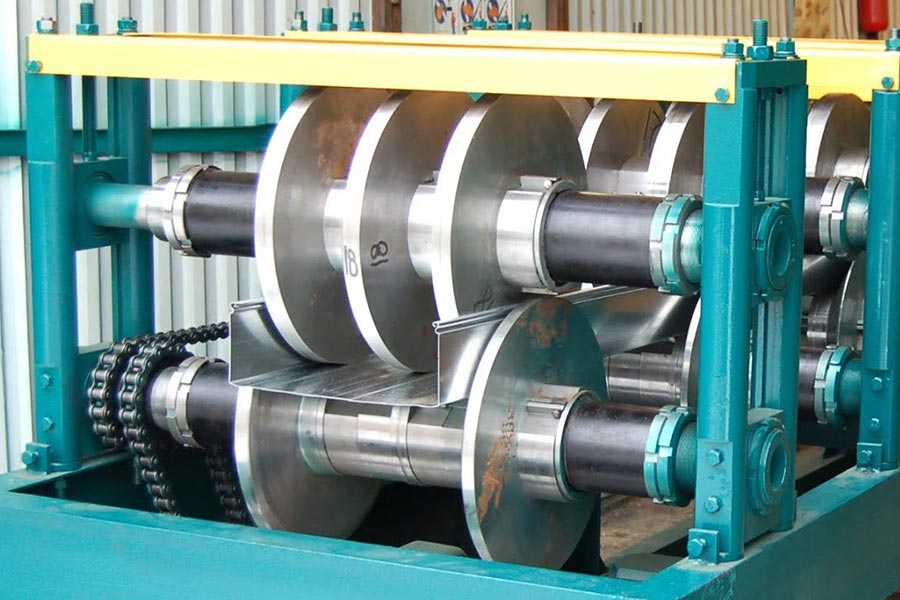

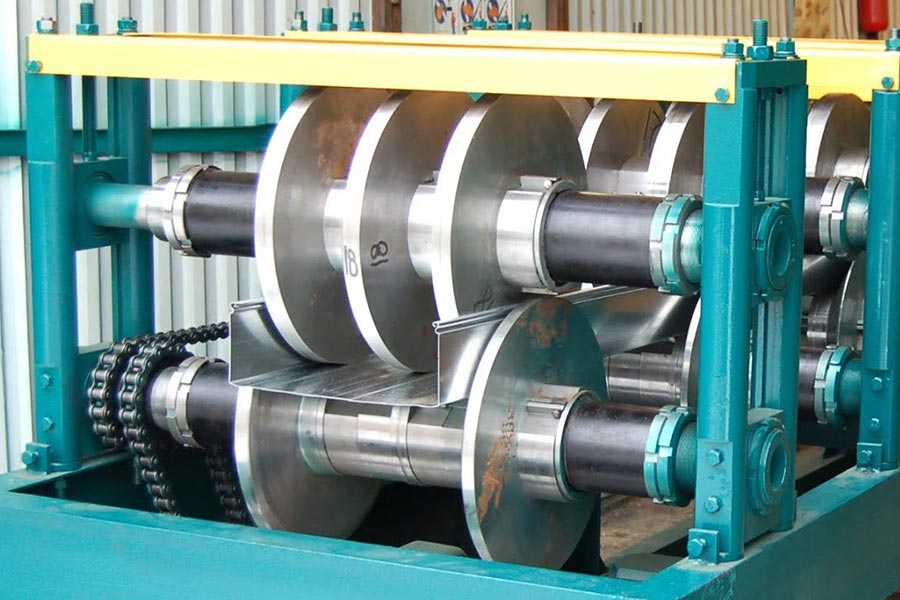

In the vast geography of the Russian Federation and in harsh climatic conditions, the construction industry is in a constant state of development with critical factors such as speed, durability and cost-effectiveness. In this dynamic environment, roll-forming technology forms the steel backbone of the Russian construction industry by precisely and quickly converting metal sheets into structural profiles. Thanks to the numerous advantages it offers compared to traditional methods, profiles produced by roll forming machines play a key role in shaping the modern face of Russia in a wide range from residences to industrial facilities, from infrastructure projects to commercial buildings.

The Place and Importance of Roll Forming Technology in the Russian Construction Industry

Roll forming technology is of strategic importance due to its potential to optimize construction processes, especially in a country like Russia, which is witnessing large-scale projects and rapid urbanization. The dominant role of this technology in the Russian construction industry is manifested in the following key areas of application:

- Roof and Facade Systems: Aesthetics, Durability and Speed Combined Russia's harsh winters and variable weather conditions necessitate high-performance roofing and cladding materials for buildings. Produced by roll form technology:

- Trapezoidal Sheets and Metal Tiles: Trapezoidal profiles made of galvanized or painted sheets (for example, C8, C21, HC35, H60, which are common in the Russian market) and metal tiles stand out with their lightness, ease of installation, longevity and resistance to snow load. These products are also preferred in terms of water tightness and ease of maintenance.

- Sandwich Panels: Sandwich panels, which are produced in roll form lines by placing insulation material (rock wool, polyurethane, etc.) between two metal sheets, offer excellent solutions in heat and sound insulation. It enables the creation of a fast and energy-efficient outer shell, especially for industrial buildings, warehouses and commercial structures.

- Metal Facade Coatings (Siding): Metal sidings, which offer an aesthetic appearance with different color and texture options, provide protection against external factors while giving buildings a modern identity.

- Light Steel Construction Systems (LSTC - ЛСТК): A Revolutionary Solution in Construction Perhaps one of the most revolutionary applications of roll forming technology in the Russian construction industry is the production of Light Steel Structure (LSTC or ЛСТК with its Russian abbreviation) profiles. The advantages of this system include:

- Quick Installation: Manufactured to precise dimensions in the factory and quickly assembled in the field, LSTC profiles significantly shorten traditional construction times. This is a great advantage, especially for regions with a short construction season.

- Cost-Effectiveness: Minimal material waste, the need for lighter foundations, and reduced labor time reduce overall project costs.

- Design Flexibility: This system, which can be easily adapted to different architectural designs, allows wide openings to be passed.

- Durability and Safety: Profiles made of high-strength galvanized steel are resistant to corrosion, fire and seismic activities.

- Environmentally Friendly: Steel contributes to sustainable construction practices because it is a recyclable material. LSTC is increasingly preferred in Russia, especially for low-rise residential buildings, social facilities, commercial buildings, agricultural structures and modular constructions.

- Drywall Profiles and Interior Applications Galvanized steel C and U profiles, which are used in the creation of indoor partition walls and suspended ceilings, are produced with high speed and precision in roll forming machines. These profiles are an indispensable part of interior designs, offering ease of installation and the opportunity to obtain smooth surfaces.

- Drainage Systems and Other Auxiliary Profiles Metal rain gutters, downspouts and their fittings, which are critical for the stormwater management of buildings, are also effectively produced with roll forming technology. In addition, various support profiles, floor profiles and special-purpose structural elements can be manufactured with this method.

Strategic Advantages of Roll Forming for the Russian Construction Industry

- Production Speed and Efficiency: Mass production capacity quickly meets the material needs of large projects.

- Dimensional Precision: Thanks to computer-controlled machines, high dimensional consistency is ensured in the profiles produced, which minimizes fit problems during assembly.

- Material Optimization: Roll forming optimizes material usage with minimum wastage.

- Logistics Convenience: Transportation and storage of light steel profiles reduces logistics costs, especially in the wide geography of Russia.

- All-Season Construction Opportunity: Dry construction techniques, especially LSTC, are less affected by weather conditions, allowing construction processes to continue throughout the year.

Result

Roll forming technology has a central role in the modernization of the Russian construction industry and overcoming the challenges it faces. With advantages such as speed, cost-effectiveness, durability and design flexibility, this technology allows structures in Russia to be built faster, safer and more sustainably. Considering the country's ongoing infrastructure development goals and housing needs, the importance of roll forming technology and innovative building profiles produced with this technology in the Russian construction sector will continue to increase in the future.