The roll forming machine manufacturing process is more than just a simple process where metal and engineering come together, it is a complex and meticulous journey similar to the creation of a work of art in itself. These machines play a vital role in shaping the numerous profiles that form the backbone of modern industry, and their production is an equally vital process that requires ingenuity and precision. The birth of a roll forming machine begins at the design stage, with each part being carefully manufactured, put together perfectly, and finally rigorously tested to perfection. This process requires a perfect harmony of engineering disciplines, technological capabilities and human skill, just as different instruments form a harmonious symphony under the direction of an orchestra conductor.

1. Design and Engineering Phase: Laying the Foundations of Excellence

Every successful roll forming machine relies on a solid foundation of design and engineering. This stage forms the soul and character of the machine.

- Needs Analysis and Specification Determination: The manufacturing process begins with an in-depth analysis of the needs of potential customers or the market. Which profiles will be produced? What materials will be processed? What speed and precision requirements will be met? The answers to these questions determine the basic characteristics and design parameters of the machine.

- Concept Design and Modeling: Engineers design the general concept and basic components of the machine in accordance with the specified specifications. At this stage, 3D models of the machine are created using CAD (Computer Aided Design) software. These models allow the visualization of the machine, the optimization of the layout of components, and the detection of potential design problems at an early stage.

- Detailed Engineering and Simulation: After the concept design is approved, detailed engineering studies begin. Detailed technical drawings of each component (body, forming stations, rollers, drive system, cutting unit, etc.) are prepared. Material selections are made, strength calculations are performed, and the performance of the machine is pre-tested using simulation tools such as FEA (Finite Element Analysis). These simulations are critical to verify the robustness, durability, and performance of the design.

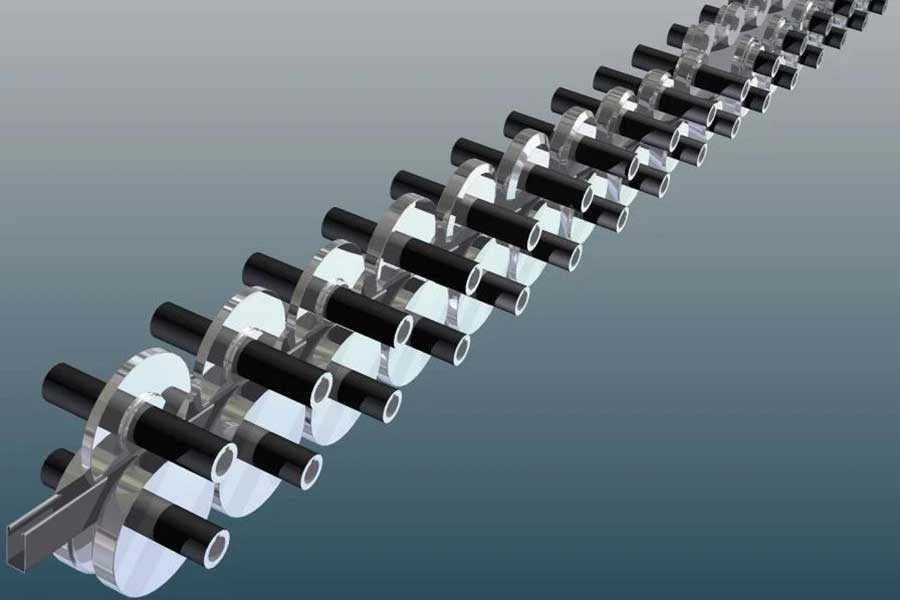

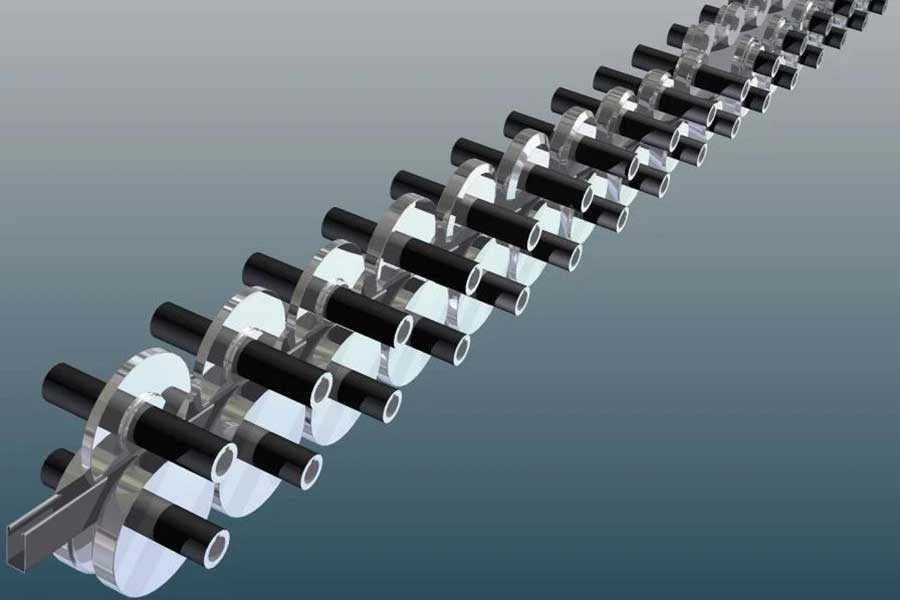

- Roll Tool Design and Optimization: The heart of the roll forming machine is the forming rollers (roll tool). These rollers, which are specially designed for each profile, are responsible for giving the metal strip the desired shape. Roll tool design requires great precision and expertise, depending on the geometry of the profile, material properties and manufacturing tolerances. The profiles of the rollers are usually optimized with CAD/CAM software and verified by simulations to enable step-by-step forming.

- Material Selection and Standardization: Suitable materials are selected for all components of the machine. Materials such as high-strength steels for the body, special wear-resistant alloys for the rollers, quality gears and bearings for the drive system ensure that the machine is long-lasting, reliable and high-performance. Standardization facilitates the availability of spare parts and helps reduce production costs.

2. Component Manufacturing: Building Precision and Quality

After the design phase is completed, the production of the components of the machine begins. This stage requires high-precision manufacturing techniques and strict quality control processes.

- Machine Body Production: The machine body generally consists of welded steel construction. Body parts are precisely cut on laser or plasma cutting machines, then assembled by expert welders. Welding processes are done meticulously to ensure strength and stability. Stress relieving after welding ensures that the body is long-lasting and stable. The body is machined on precision machining centers, guaranteeing the smoothness of the mounting surfaces and the accuracy of the dimensions.

- Forming Stations and Mechanisms: Forming stations are critical components where the roll forming process takes place and carry the rollers. These stations are manufactured on high-precision CNC machining centers. Roller bearings, adjustment mechanisms, and other moving parts are machined with micron-level tolerances. The rigidity and vibration-free operation of the stations are vital for profile quality.

- Roll Tool (Rollers) Production: The roll tool is the most critical and specialized component of the roll forming machine. Rollers are usually produced from special tool steels on CNC turning and milling machines. Precise profiles suitable for profile geometry are obtained thanks to programs created with CAM (Computer Aided Manufacturing) software. The rollers are subjected to heat treatment to increase surface hardness and wear resistance. Their surface is smoothed by precise grinding and polishing processes. Each roller is meticulously inspected for dimensional accuracy and surface quality during the quality control phase.

- Drive System Components: The drive system is the power supply that makes the rollers rotate and the metal strip advances. Drive system components such as gearboxes, gearboxes, motors, couplings and shafts are often sourced from specialist suppliers. The selection of these components is made according to the power requirements, speed range and torque requirement of the machine. The drive system is integrated into the machine during the assembly phase and precisely adjusted.

- Cutting Unit Production: Cutting units ensure that the produced profile is cut to the desired lengths. Different design and production approaches are applied according to different cutting methods (flying saw, hydraulic shear, rotary cutting, etc.). Cutting blades or saw teeth are made of high-quality tool steels and hardened by heat treatment. Fast, precise and clean cutting of cutting units is important in terms of production efficiency and profile quality.

- Control Panel and Electrical Systems: The control panel and electrical systems, which control and automate all functions of the machine, are designed and installed by expert electrical engineers. Electrical and electronic components such as PLC (Programmable Logic Controller), HMI (Human-Machine Interface), drives, sensors, and cables are selected from trusted and well-known brands. The control panel is wired and tested in accordance with the standards. PLC software is programmed to control the machine's working cycle, speed, cutting length and other parameters.

3. Assembly and Integration: Transforming the Parts into the Whole

All the components produced and supplied are brought together on the assembly line to form a roll forming machine. This stage requires careful and meticulous work.

- Body Assembly: The machine body forms the basis of the assembly process. The body is precisely aligned and fixed. All other components shall be mounted on the body.

- Installation of Forming Stations: Forming stations are precisely placed on the body and secured with bolts or other fasteners. Mounting the stations in the correct position and angle is critical for the correct shaping of the profile.

- Assembly of Roll Sets (Rollers): Rollers are mounted on forming stations. The placement of the rollers in the right order and with the right gaps ensures a gradual shaping of the profile. Roller adjustments are made precisely according to the profile to be produced.

- Drive System Integration: Drive motors, gearboxes and other drive system components are connected to forming stations. The drive system ensures synchronized and controlled rotation of the rollers.

- Installation of the Cutting Unit: The cutting unit is mounted at the end of the forming line. The alignment and synchronization of the cutting unit is important for smooth and error-free cutting of the profile.

- Connection of Electrical and Control Systems : The control panel is wired to electric motors, sensors, drives, and other electrical components. Electrical connections are made in accordance with safety standards and schemes. The PLC program is installed and the control system is tested.

- Integration of Hydraulic and Pneumatic Systems (if applicable): Hydraulic and pneumatic systems (e.g., hydraulic scissor cutting units or pneumatic clamping systems) are integrated into the machine. The connections and settings of these systems are carefully made for safe and efficient operation.

4. Testing & Quality Control: Confirmation of Excellence

After the assembly process is completed, the roll forming machine is subjected to a comprehensive testing and quality control process. This step is vital to verify that the machine meets the design specifications and can operate safely.

- Mechanical Tests: The mechanical parts of the machine are tested by operating them at idle and under load. The rotation of the rollers, the performance of the drive system, the operation of the cutting unit and the smoothness of all moving parts are checked. Vibration and noise levels are measured.

- Electrical Tests: Electrical systems are tested for compliance with safety standards and functionality. Short circuit tests, insulation tests, grounding tests and functional tests are performed. The correct operation of the control panel, PLC program and operator interface is verified.

- Profile Production Tests: The machine is evaluated for performance by producing test profiles in different materials and thicknesses. The dimensions, shapes, surface quality and mechanical properties of the produced profiles are measured and compared with the design specifications. Speed tests are carried out to verify that the machine has reached the production speed of заявленный.

- Quality Control Stages: There are quality control points at every stage of the production process. Different quality control procedures are applied during component production, assembly and testing stages. In the final quality control stage, all functions, performance and safety of the finished machine are thoroughly inspected. Quality control reports are prepared and the conformity of the machine is confirmed.

5. Finishing & Delivery: Perfection Reaching Customer

The roll forming machine, which has successfully passed the test and quality control stages, is ready to be delivered to the customer after the final processes.

- Surface Treatments and Painting: The machine body and other metal parts are painted or coated to protect against corrosion and improve the aesthetic appearance. The choice of color is usually made according to the customer's request.

- Labeling and Marking: Necessary labeling such as safety labels, warning signs, brand information and serial number are made on the machine.

- Packaging & Shipment: The machine is carefully packed to avoid damage during transportation. Usually, the machine is placed and fixed on crates or pallets for overseas or long-distance shipments. Final checks are made before shipment and necessary documents are prepared.

- Installation & Training (Optional): Depending on customer request, the machine manufacturer can provide installation service and operator training. Installation ensures that the machine starts working correctly and safely. The training enables operators to operate and maintain the machine efficiently and safely.

In conclusion, the roll forming machine manufacturing process is a long and arduous journey that combines complex engineering disciplines, precision manufacturing techniques, and rigorous quality control processes. Starting from the design stage, this process aims to achieve perfection by carefully manufacturing, flawlessly assembling and meticulously testing each component. Roll forming machines are indispensable production tools of modern industry, and their production process is just as valuable and important. The care, precision and expertise shown in this process guarantee that roll forming machines are long-lasting, reliable and high-performance and make significant contributions to industrial production.