Our company operating on electro-mechanical production processes, our company has experience for more than 27 years with its high-tech production structure and provides service to the industry.

The production structure is adapted to the continously developing trends of the industry. Our company shapes a proactive management approach, achieving goals He saw it as a necessary principle to reach and implemented it.

With its advanced R&D structure, from the beginning to the end of the production process, carrying out the operations with great care, using modern methods and techniques constantly improving product and service quality, ensuring growth, quality and success. Our company, which sees renewable targets, follows the marketing It has gained an important place in the sector with its strategies.

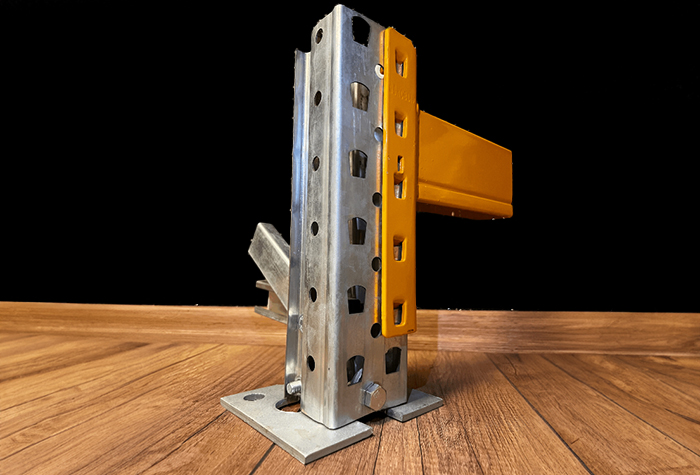

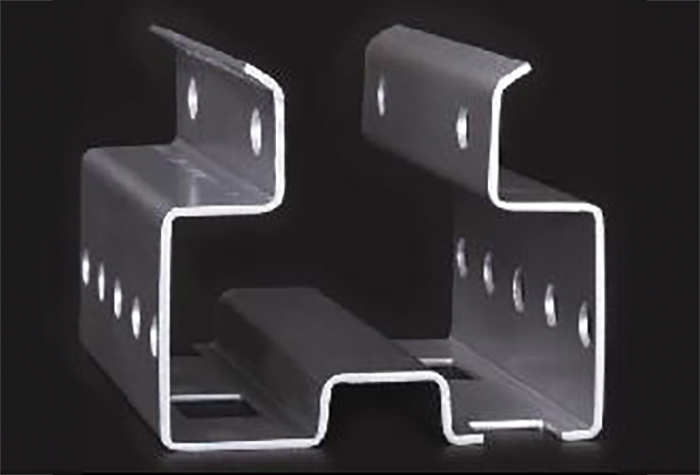

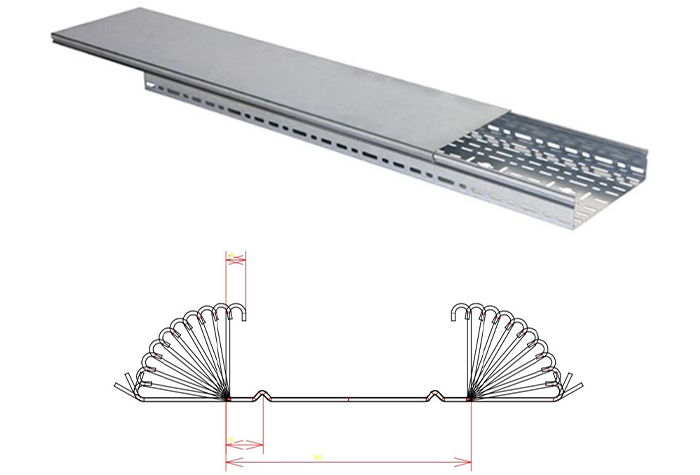

According to the appropriate program, the stress of the sheet metal is determined, our experience is added and the design is made. Manufacturing is done using the latest technologies required by the age and the job. Parts machined on precision machines in accordance with their tolerances are collected by our experienced team.