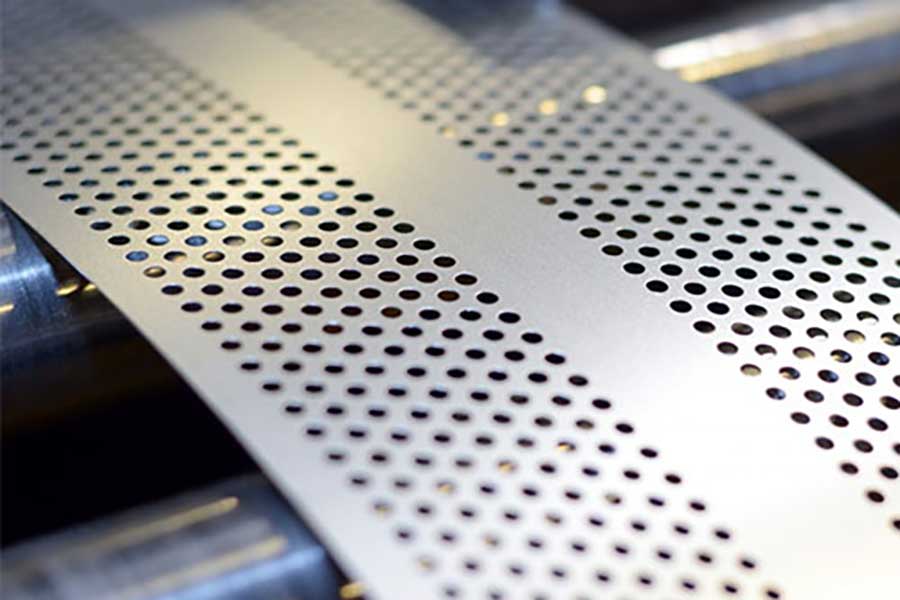

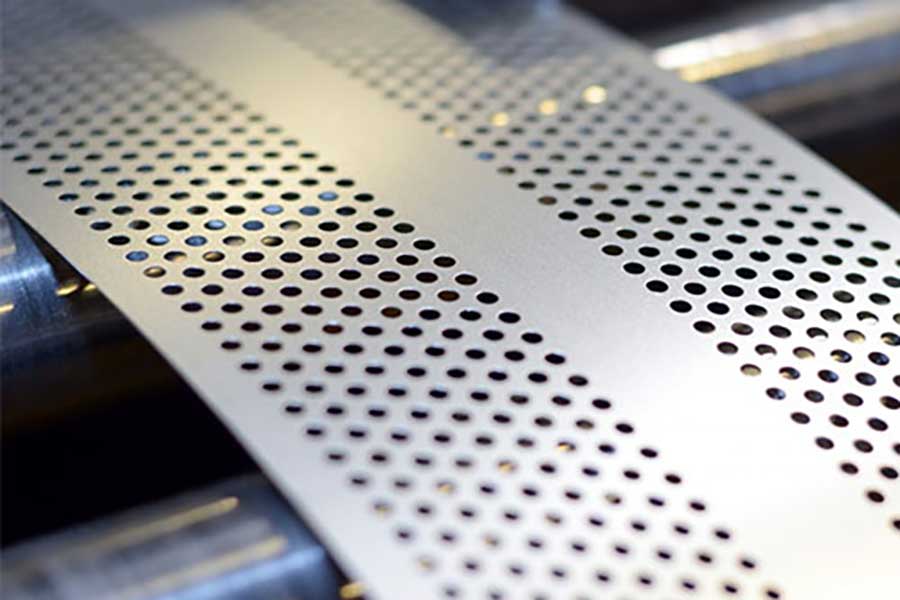

The production of perforated and non-perforated profiles in roll forming machines is one of the applications that best demonstrates the flexibility and adaptability of metal forming technology. Although they basically use the same roll forming principles, the production processes of perforated and non-perforated profiles differ significantly, especially in terms of the integration and control of the boring process. Both profile types are used in a wide range from construction to automotive, from white goods to ventilation systems, and roll form technology enables these profiles to be produced with high efficiency, precision and cost-effectiveness.

Roll Forming Basic Principle: Common Ground

Whether perforated or non-perforated, roll form profile production is based on the same principle: gradual forming. The flat metal strip (sheet) passes through a series of sequentially placed forming rollers (rollers). Each set of rollers exerts a slight shape change to the metal. Through this gradual and continuous bending process, the metal strip is shaped step by step until it reaches the desired profile shape. This process enables the production of complex profiles with high speed and precision by providing a controlled deformation without applying sudden and excessive force to the metal.

Non-Perforated Profile Production: Standard Roll Forming

Perforated profile production is the most basic and common application of roll forming technology. In this process, the metal strip is only shaped by passing it through the forming rollers and cut to the desired lengths in the cutting unit.

- Material Feeding: The metal strip in the form of a coil is placed in the uncoiler unit and advanced to the forming line in a controlled manner.

- Straightening: If necessary, the metal strip is straightened by passing it through the straightening rollers.

- Roll Forming: The metal strip is passed through a series of forming stations and gradually takes the shape of a profile. Each station contains specially designed rollers that shape a specific part of the profile.

- Cutting: After the forming process is completed, the continuous profile is cut to the desired lengths by the cutting unit (usually a flying saw or scissors).

- Stacking: The cut profiles are stacked in regular bundles by the automatic stacking unit.

The non-perforated profile production line has a relatively simple structure and is capable of continuous production, usually at high speeds. Manufactured profiles are used in many applications that require strength, structural integrity, or surface area.

Perforated Profile Production: Integration of Boring Process

In addition to the perforated profile production process, perforation production requires the integration of the perforation process. Holes can be drilled to increase the functionality of the profile, reduce its weight, provide ventilation, facilitate installation or for aesthetic purposes. The drilling process can be integrated into the roll forming line at different stages:

- Pre-Punch: In this method, the metal strip is drilled in a separate press unit or a special punching machine before entering the roll forming line. The perforated sheet coils are then loaded onto the roll forming line and formed following the standard perforated profile production process.

- Advantages:

- High Speed: Since the drilling process is done separately from the roll forming process, it does not affect the overall production speed of the line. High-speed, continuous production is possible.

- Complex Hole Patterns: Holes of different sizes, shapes, and complex patterns can be drilled. The press unit offers more flexibility.

- Thick Materials: Drilling holes in thick and high-strength materials may be easier with the pre-punch method.

- Disadvantages:

- Material Management: Separate preparation and management of perforated sheet coils requires additional logistics and material handling.

- Loss of Precision: Because the holes are drilled before the roll forming process, slight shifts or deformations may occur during profile forming, and the location of the holes may affect their precision.

- Limited Hole Position Control: The position of the holes on the profile cannot be precisely controlled during the roll forming process.

- In-line Punch / Post-Punch: In this method, the drilling process is carried out by a special drilling unit integrated into the roll form line. The drilling unit is usually placed between the forming stations or at the end of the line. The holes are drilled during or immediately after the profile forming process.

- Advantages:

- High Precision: Because the holes are drilled synchronously with the profile forming process, the position of the holes can be controlled more precisely on the profile.

- One Process, Fewer Operations: Since drilling and profile forming processes are combined on a single line, the number of material handling and operations is reduced, and the production process becomes more efficient.

- Hole Position Flexibility: The position of the holes can be adjusted more flexibly according to the profile shape and production requirements.

- Disadvantages:

- Production Speed Limitation: The punching process can limit the speed of the roll forming line. Drilling speed becomes a critical factor in determining the overall production speed of the line.

- Limited Hole Complexity: In-line drilling units are generally suitable for simpler hole shapes (round, square, rectangle) and patterns. It may not be suitable for complex hole patterns or large holes.

- Tool Wear and Maintenance: Punch and die in in-line drilling units can be subject to increased wear at high speeds and continuous operation and require regular maintenance.

Perforated Profile Production Line Components (Additionally):

In addition to the standard non-perforated profile line, the perforated profile production line can include the following components:

- Punching Unit: A special punching unit that uses one of the pre-punch, in-line punch or post-punch methods, depending on the design of the line. This unit can be hydraulic or servo-controlled and must be capable of drilling precise holes at high speeds.

- Punch and Die Sets: The punch and die used in the drilling unit are specially designed and produced according to the shape, size and material properties of the holes to be drilled. Tool materials are selected from special tool steels that are resistant to wear.

- Synchronization and Control System: An advanced control system that ensures that the punching process works synchronously with the roll forming process. PLC (Programmable Logic Controller)-based control systems precisely manage drilling timing, hole position, profile speed, and other parameters. Encoders and sensors provide position feedback, increasing drilling accuracy.

- Scrap Management System: Metal particles (scrap) formed during the drilling process should be collected and removed automatically. The scrap management system ensures the clean and efficient operation of the production line.

Things to consider in the production of perforated profiles:

- Material Distortion: The drilling process may cause distortion or deformation of the metal strip. Especially in thin materials or when drilling large holes, the risk of distortion increases. Roller design and drilling parameters must be optimized to minimize distortion.

- Hole Quality and Precision: The diameter, position, shape and surface quality of the holes are important for the functionality and appearance of the product. The sharpness of drilling tools, drilling speed, and material properties are all factors that affect hole quality.

- Tool Wear and Maintenance: Drilling tools are subject to wear in continuous and high-speed operation. Regular maintenance, lubrication and tool changes extend tool life and maintain hole quality.

- Scrap Management: Scrap resulting from drilling must be managed effectively. Automated scrap collection and removal systems improve the efficiency and safety of the production line.

Perforated and Non-Perforated Profile Application Areas:

- Perforated Profiles:

- Structural Profiles: C, U, Z, Sigma profiles, purlins, beams, columns

- Roof and Facade Systems: Trapezoidal sheet, corrugated sheet, sandwich panel edge profiles

- Automotive Parts: Chassis elements, body parts, door frames

- White Goods Profiles: Refrigerator, washing machine case profiles

- Rack and Storage Systems: Shelf uprights, sleepers

- Perforated Profiles:

- Cable Trays and Tray Systems: Perforated ducts for ventilation and cable management

- Ventilation and Air Conditioning Systems (HVAC): Vents , air ducts, filter frames

- Solar Panel Mounting Systems: Lightened mounting profiles, ventilated systems

- Acoustic Panels and Ceiling Systems: Sound absorbing panels, decorative ceiling elements

- Agriculture and Greenhouse Structures: Ventilated greenhouse profiles, drainage channels

As a result, roll forming technology offers great flexibility and efficiency in the production of both perforated and non-perforated profiles. Perforated profile production adds additional functionality to the standard process with the integration of the drilling process into the roll forming line. With the right choice of method, proper equipment and precise control, roll forming machines provide the possibility to produce high-quality and customized perforated and non-perforated profiles for a wide range of applications. By taking into account your production needs and profile requirements, you can choose the most suitable roll form line configuration and create an efficient production process.