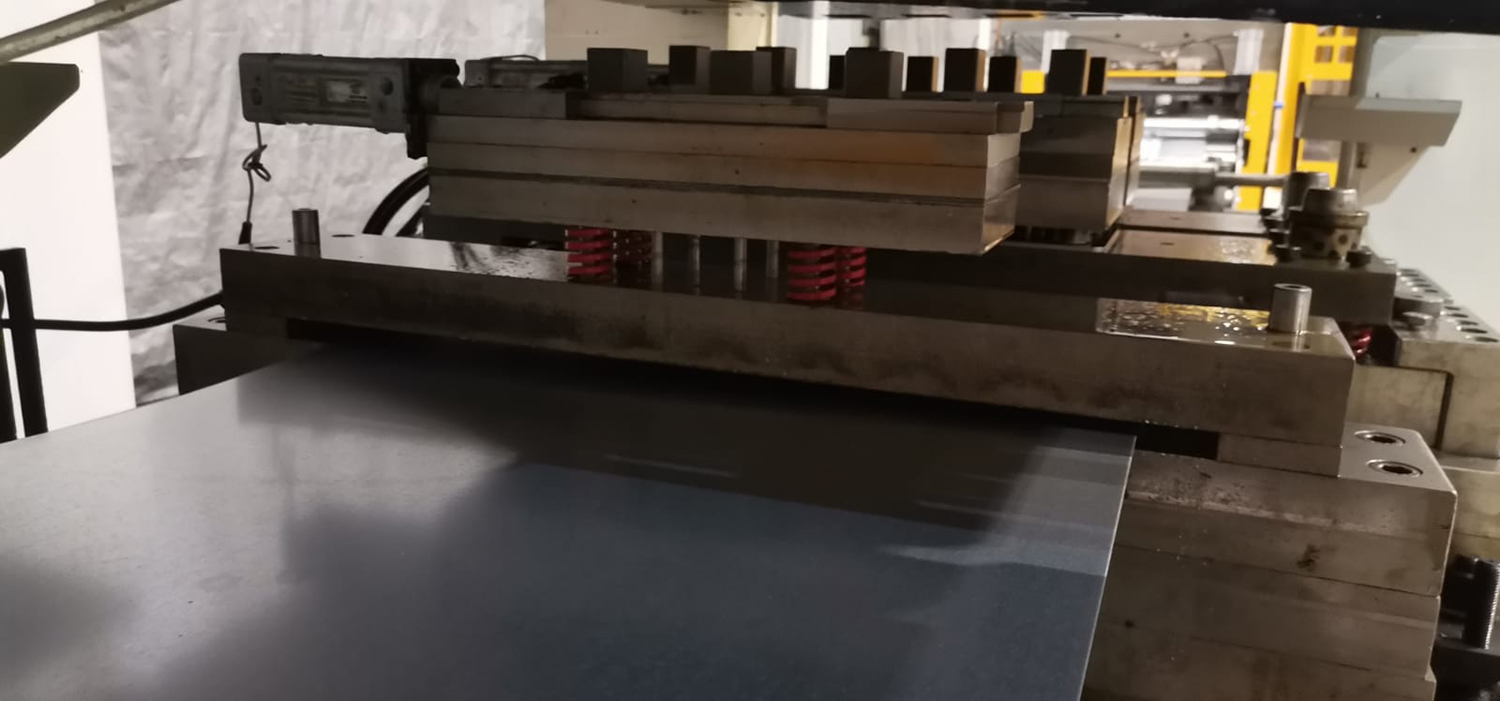

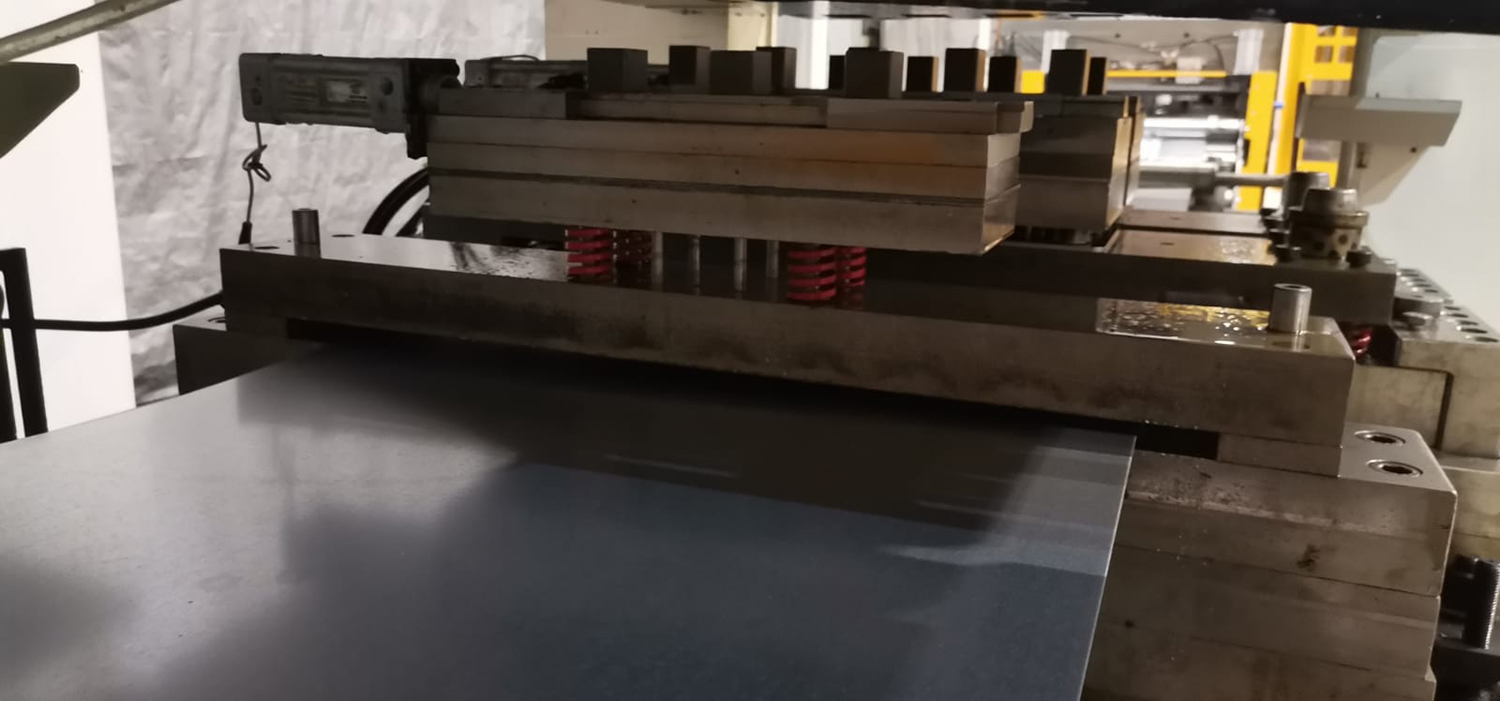

Punch presses used in roll forming lines are a process generally applied to metal sheets. However, the type of material that can be machined depends on many factors, such as the strength of the punch press, the molds used, and the geometric properties of the workpiece to be machined.

In general, the materials that can be processed are:

- Steel: Different types of steel are frequently processed, such as forged steel, sheet steel, stainless steel, etc.

- Aluminum: Due to its light weight and easy machinability, aluminum sheets are also frequently used.

- Copper: Copper plates can also be machined because of its high electrical conductivity.

- Brass: Brass plates are also preferred due to their corrosion resistance.

- Stainless Steel: Due to its durability and aesthetic appearance, stainless steel plates are also processed.

Non-machinable or difficult-to-process materials:

- Very hard alloys: High hardness alloys such as chromium and tungsten can be difficult to machine.

- Very soft metals: Very soft metals, such as lead, can be deformed.

- Plastics: Since punch presses are usually designed for metals, different machines are used for processing plastics.

The choice of material is made depending on the following factors:

- Purpose of use of the product: The material is selected according to the properties of the product such as durability and corrosion resistance.

- Environmental conditions: Conditions such as temperature and humidity to which the product will be exposed have an effect on material selection.

- Cost: The cost of the material is also an important factor.

- Machinability: The punch press machinability of the material affects factors such as mold life and energy consumption.

In summary, punch presses used in roll forming lines can process a variety of metal sheets. However, the choice of material is determined by the characteristics of the product, the production conditions and the capacity of the punch press.

Things to consider:

- Mold material: The material of the mold should be suitable for the hardness and temperature of the material to be processed.

- Punch force: A punch press with sufficient strength should be used according to the thickness and hardness of the material to be processed.

- Cooling: In some cases, cooling systems are used to prevent the heat generated during processing from damaging the material.

- Lubrication: Lubrication can be done to reduce friction between the mold and the material.