Maintenance of Rectifier Elements

1. Regular Visual Inspections: Regular visual inspection of the rectifier elements allows early detection of signs of wear, damage, or deterioration. During these checks, particular attention should be paid to the condition of the rolls and bearings.

2. Lubrication: The moving parts of the rectifier elements should be lubricated regularly. The use of appropriate lubricants reduces friction, extending the life of the parts and keeping the machine running efficiently.

3. Cleanliness: Keeping the rectifier elements clean prevents accumulated dust and metal particles from damaging the mechanical components. Cleaning should be done at regular intervals.

4. Alignment and Calibration: In order for the rectifier elements to function properly, they must be correctly aligned and calibrated. Calibration processes ensure that metal sheets are straightened properly and improve production quality.

Spare Parts

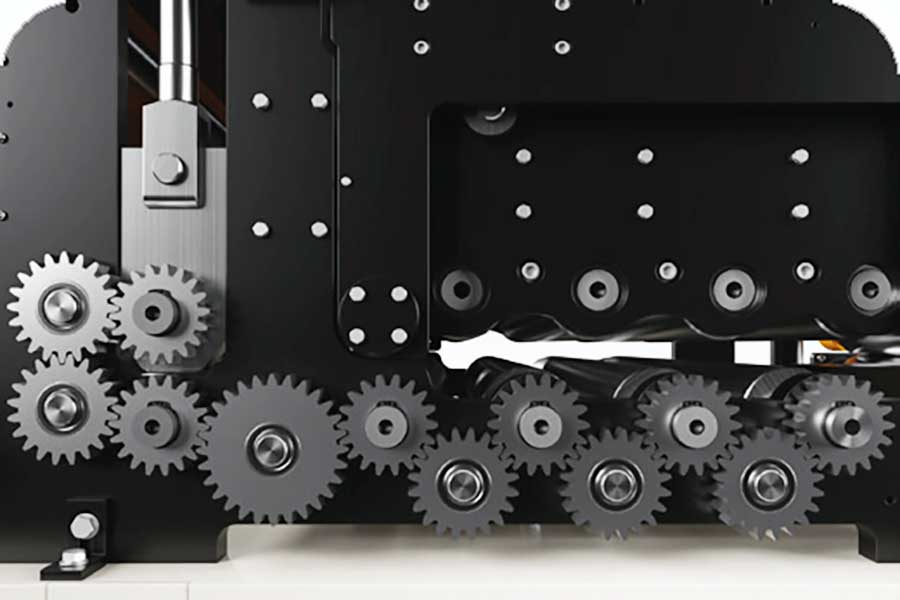

1. Rolls: Rolls are one of the most important parts of rectifier elements. They can wear out over time and may need to be replaced. The use of quality rolls increases the precision and efficiency of the straightening process.

2. Bearings: Bearings are the parts that ensure the smooth rotation of the rolls. They should be replaced when they are worn or damaged. High-quality bearings ensure smooth operation of rolls.

3. Hydraulic and Pneumatic Parts: The opening, closing and alignment of metal sheets of rectifier elements are usually carried out by hydraulic or pneumatic systems. The valves, cylinders, and hoses used in these systems can wear out over time and need to be backed up.

4. Springs and Fasteners: Springs and fasteners, which are the structural parts of rectifier elements, can wear out or break over time. It is important to check such components regularly and replace them as needed.

Maintenance and Spare Parts Management

1. Maintenance Program: A program should be established to ensure regular maintenance of the straightening elements. This program includes performing maintenance operations at regular intervals and checking all parts.

2. Spare Parts Stock: Constant availability of critical spare parts ensures that any potential malfunctions are rectified quickly. It is also important to regularly replenish the stocks of spare parts.

3. Training and Awareness: Training operators and maintenance personnel on the maintenance of straightener elements and replacement of spare parts is essential for the smooth operation of the machine. Trainings ensure that employees are aware and possible mistakes are prevented.

Result

Maintenance and spare parts of the rectifier elements used in roll forming lines are of great importance in terms of the efficiency and production quality of the line. Regular maintenance and proper spare parts management ensure the smooth operation of the rectifiers and make it possible for production processes to continue uninterrupted. Therefore, it is necessary to give due importance to the maintenance of rectifier elements and the supply of spare parts.