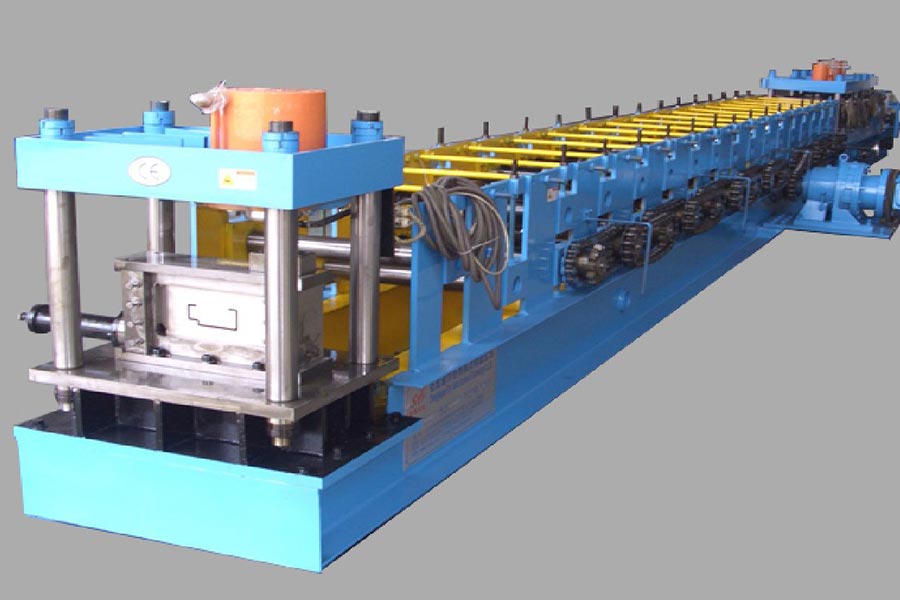

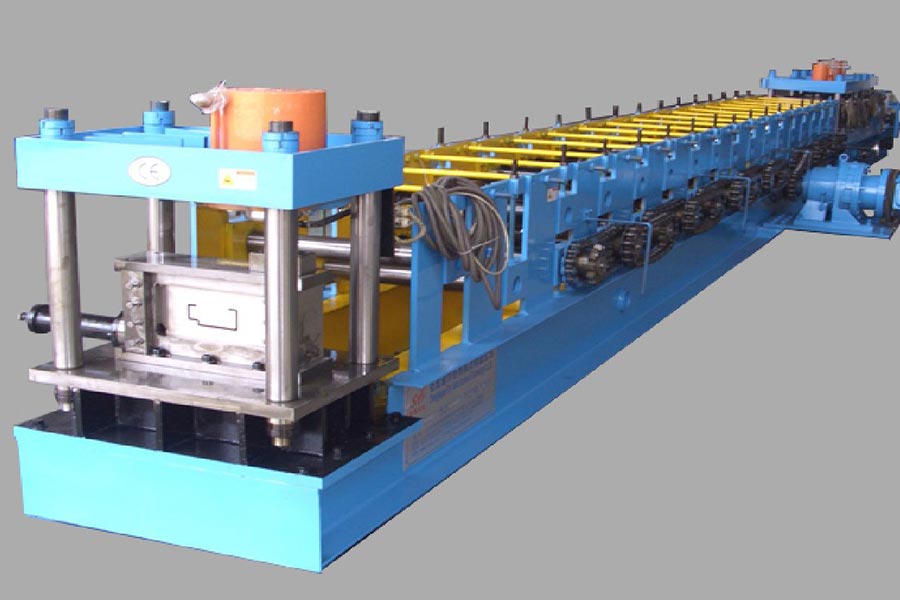

Roll forming technology is the backbone of many industrial sectors in the Russian Federation, enabling metal sheets to be quickly and precisely converted into desired profiles. Thanks to its high production speed, material efficiency and low operating costs, roll forming machines play a critical role in the competitiveness of Russian industry. These machines offer a wide range of innovative solutions, from construction to automotive, from energy to general manufacturing.

The industrial application areas of roll forming machines in Russia vary in direct proportion to the geographical size of the country, its rich natural resources and developing infrastructure projects. Here are the main areas of use of this technology in Russian industry:

1. Construction Industry: Fast and Reliable Foundation of Structures

Russia's harsh climatic conditions and vast geography increase the demand for durable and quick-to-assemble building materials. Roll forming machines are revolutionizing the construction industry by responding to this need:

- Roof and Facade Systems: Trapezoidal sheets made of galvanized steel and painted sheets (for example, profiles such as C8, C10, C21, C44, which are common in the Russian market), sandwich panels and metal tiles are manufactured with high quality and speed with roll form technology. These products are used in a wide range of applications, from industrial facilities to residential buildings.

- Light Steel Structure Profiles (LSTC): Light steel structure profiles, which are especially preferred in low-rise building constructions, warehouse and hangar construction, are produced in precise dimensions on roll forming machines. These profiles offer advantages such as ease of installation and earthquake resistance.

- Drywall Profiles and Support Elements: C and U profiles of drywall wall and ceiling systems used in interior applications are mass-produced in roll form lines.

- Drainage Systems and Rain Gutter Profiles: Metal gutter and pipe profiles required for rainwater discharge of buildings are also shaped with this technology.

2. Automotive Industry: Lightness, Durability, and Efficiency

The Russian automotive industry makes extensive use of roll-forming technology in pursuit of its goals of reducing vehicle weight, improving fuel efficiency and raising safety standards:

- Body and Chassis Parts: Door inner support sheets, sill profiles, roof supports, in-bumper strength bars and various chassis elements of vehicles are produced by forming high-strength steels by roll forming method. This ensures that the parts are both lightweight and impact resistant.

- Seat Slides and Mechanisms: Precision profiles used in the moving mechanisms of automobile seats are manufactured with roll form.

- Trim and Decorative Parts: Some metal trims and decorative profiles inside and outside the vehicle are also produced with this method.

3. General Manufacturing & Industrial Products

The flexibility of roll forming machines allows for the manufacture of a wide range of industrial products:

- Shelf Systems and Storage Solutions: The strut and traverse profiles of metal shelving units used from supermarkets to large logistics warehouses are produced in high quantities and different sections in roll form lines.

- Cable Transport Systems: Metal cable trays and ladders used in electrical installations are manufactured with roll form in different widths and heights.

- Electrical Panels and Cabinets: Frame and panel profiles of industrial electrical panels and various metal cabinets are produced with this technology.

- Furniture Industry: Metal furniture frames, office furniture components and various joint profiles are formed on roll forming machines.

- Pipe and Profile Production: Roll form technology is a basic method in the production of welded pipes and open profiles (square, rectangular, special section) in different diameters and wall thicknesses.

4. Energy Sector: Strong Components of Infrastructure

Russia's vast energy infrastructure requires a variety of metal components that are produced in roll form:

- Solar Energy Systems Mounting Profiles: Aluminum and steel carrier construction profiles used in the assembly of solar panels are precisely produced in roll forming machines.

- Pipeline Support and Coating Elements: Special profiles can be manufactured for some support structures and protective coating elements of oil and natural gas pipelines.

- Lighting Poles and Power Transmission Line Components: Some types of lighting poles and structural metal components used in power transmission lines can be produced by roll forming method.

5. Heating, Ventilation and Air Conditioning (HVAC) Systems

Roll forming is critical in the production of metal components used to ensure air quality and energy efficiency in the HVAC industry:

- Air Duct Profiles: Clamp and flange profiles of rectangular and round air ducts made of galvanized sheet metal are manufactured to provide high sealing and strength in roll forming machines.

- Filter Frames and Vent Profiles: Filter box frames and vent fin profiles of ventilation systems are also produced with this technology.

Result

In Russia, roll forming machines are an indispensable technology that improves the efficiency and quality of industrial production, reducing costs and allowing for innovative designs. A wide range of applications, ranging from basic structural elements in the construction industry to precision components in automotive, from various profiles in general manufacturing to critical parts in the energy and HVAC sector, clearly demonstrates the strategic importance of this technology in Russian industry. In line with Russia's industrial modernization and infrastructure development goals, the demand for roll forming machines and the areas of use of this technology are expected to increase further in the future. This presents significant opportunities for both domestic manufacturers and international machinery suppliers.