A Comprehensive Look at Punch Press

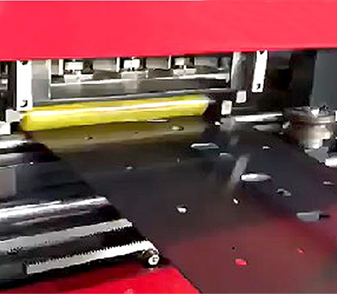

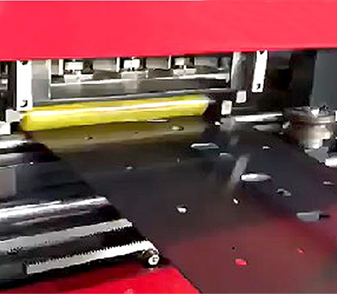

Punch Press is an industrial machine used to drill holes in metal sheets or plates in desired shapes and sizes. Simply put, with the help of a punch, it performs the process of drilling a hole in the metal at the desired point.

Working Principle of Punch Press

The punch press basically consists of the following components:

- Base: It is a fixed platform on which the material is placed.

- Column: It is a vertical structure in which moving parts are transported.

- Coach: The part with the punch on it and moving up and down.

- Punch: It is a cutting tool that drills a hole on metal.

- Die: It is the die opposite the punch that gives the shape of the hole.

- Power Source: It is the system that provides motion energy (usually hydraulic or mechanical) to the machine.

Working principle:

- Material Placement: The metal sheet or plate is correctly placed on the base.

- Descent of the Punch: The ram is moved downward by the power supply, and the punch is squeezed between the material and the die.

- Punching Process : The punch punches the material, and the die forms the shape of the hole.

- Take-off of the Punch: The ram moves up, separating the punch and material.

Types of Punch Press

Punch presses vary with different power sources, capacities, and levels of automation. Some of these include:

- Mechanical Punch Press: They are simpler and more economical models that work with a crank mechanism.

- Hydraulic Punch Press: It is suitable for operations that work with oil pressure and require high force.

- Pneumatic Punch Press: It is used for faster and more precise operations that work with air pressure.

- CNC Punch Press: Ideal for computer-controlled, complex punching operations.

Uses of Punch Press

Punch Press has a wide range of uses. It is frequently used in sectors such as automotive, white goods, electronics and metal processing. In addition to drilling, it can also be used in forming processes such as cutting and bending.

- Automotive: Drilling operations on chassis, body, body parts.

- White Goods: Drilling processes in metal cases of products such as refrigerators and washing machines.

- Electronics: Drilling operations on metal chassis of electronic devices.

- Metalworking: Drilling operations during the production of various metal products.

Advantages of Punch Press

- High Efficiency: It provides high production speeds thanks to its automatic and fast operation.

- Precision Workmanship: CNC punch presses are capable of drilling into complex and precise shapes.

- Versatility: It can perform drilling operations in different thicknesses and materials.

- Automation: Can be integrated with automatic feeding and extraction systems.

Disadvantages of Punch Press

- High Cost: CNC punch presses, in particular, can be costly.

- Noise: It can make a loud noise during operation.

- Safety Risks: Improper use may cause work accidents.

Result

Punch press is an indispensable machine in the metalworking industry. Thanks to its characteristics of high efficiency, precision workmanship and versatility, it is widely used in many industries. However, it is important to use it with attention to safety precautions.

Additional Information:

- Punch and Die Selection: The appropriate punch and die should be selected according to the thickness, shape and material of the material to be drilled.

- Maintenance: Punch presses should be maintained regularly.

- Safety: Protective equipment must be used during operation.